China’s “in-orbit factory” has taken shape following a technological breakthrough in the form of an inflatable, reconfigurable space module, as it joins the United States and other countries to build large-scale industrial production lines in orbit.

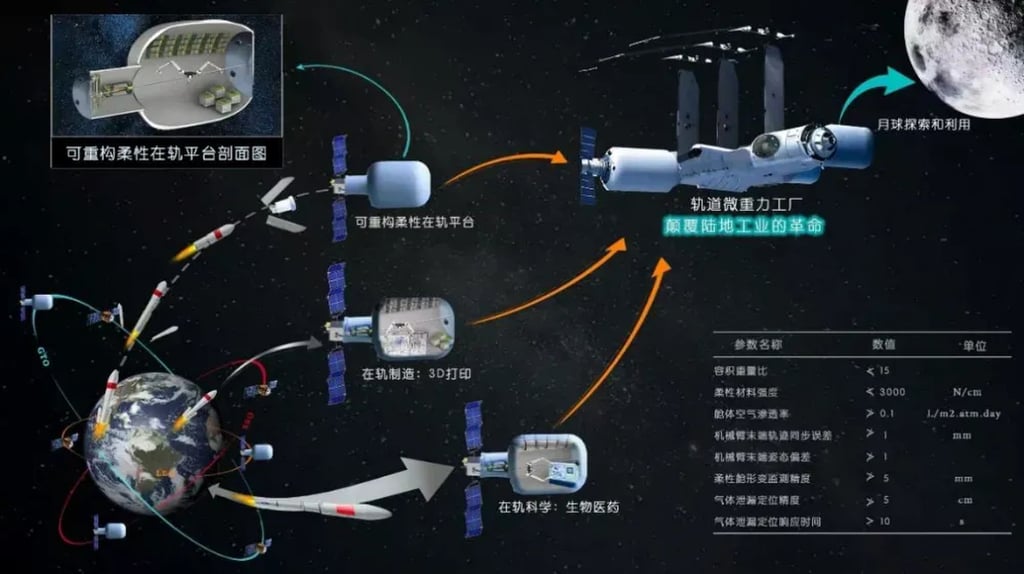

According to the developers, components of this smart morphing framework can be compactly folded during launch and inflated and unfolded once in orbit to form a vast, stable operational habitat, each a building block to create a manufacturing plant in space.

Space factories have become a new frontier in which both the public and private sectors invest. In 2023, the California-based start-up Varda Space Industries announced the successful deployment of its first satellite, W-Series 1, into orbit, calling it the “world’s first space factory”.

Director of the Institute of Mechanics’ Sky Flight Science and Technology Centre Yang Yiqiang, who is overseeing the project, said the technology would propel China’s space manufacturing from “concept verification” to “engineering realisation”.

“We will be able to manufacture and produce directly within the space environment, achieving independent development and utilisation of space resources,” he said.

The advancement was recently detailed by the Institute of Mechanics, an affiliate of the Chinese Academy of Sciences (CAS).

According to a statement issued by the Beijing-based institute on November 3, it recently tested a key module of the space factory – known as the “reconfigurable flexible in-orbit manufacturing platform” – in collaboration with several other domestic research bodies.