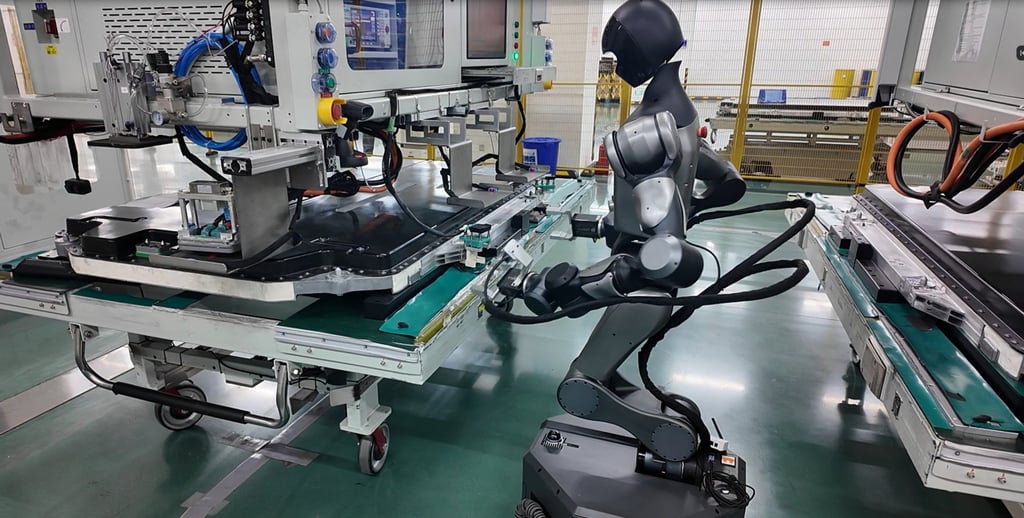

The company on Wednesday described its deployment at scale as a “world’s first”, as humanoid robots built by start-up Spirit AI performed complex tasks with speeds that matched those of skilled human workers.

Spirit AI’s Xiaomo robots have been assigned to plug in high-voltage battery connectors on the assembly line, according to CATL. This traditionally manual part of EV battery production had long been considered a security risk for human workers.

Powered by CATL batteries, the Xiaomo robots are equipped with a Vision-Language-Action artificial intelligence model that enables them to recognise changes in their environment, such as a different plug-in position, and adjust their grip in real time.

Apart from achieving a 99 per cent success rate at its plug-in task on CATL’s factory floor, Xiaomo’s daily workload was also triple that of a human worker because these machines work without any breaks, according to the company.

CATL said it would further improve the level of automation and intelligence at its factories, while pushing for broader adoption of embodied AI – AI systems that are integrated into physical bodies, such as robots or autonomous machines.